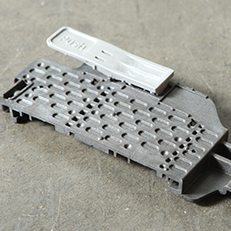

When you have the need to create a large quantity with tight tolerances of a product, injection molding is often the right solution. In the injection molding process, material is heated, blended and injected into a mold cavity. The molten plastic then cools and hardens to fit the shape of the mold. Injection molding is versatile and is used in the manufacturing of countless parts of all sizes.

Injection Molding

Our Custom Injection Molding Capabilities

Our 35-Injection molding presses range from 120 ton to 500 ton with shot size from 4oz to 60oz. The injection molding facilities operate under a 5 days-per-week, 24-hour schedule with weekends available to react to demand spikes.